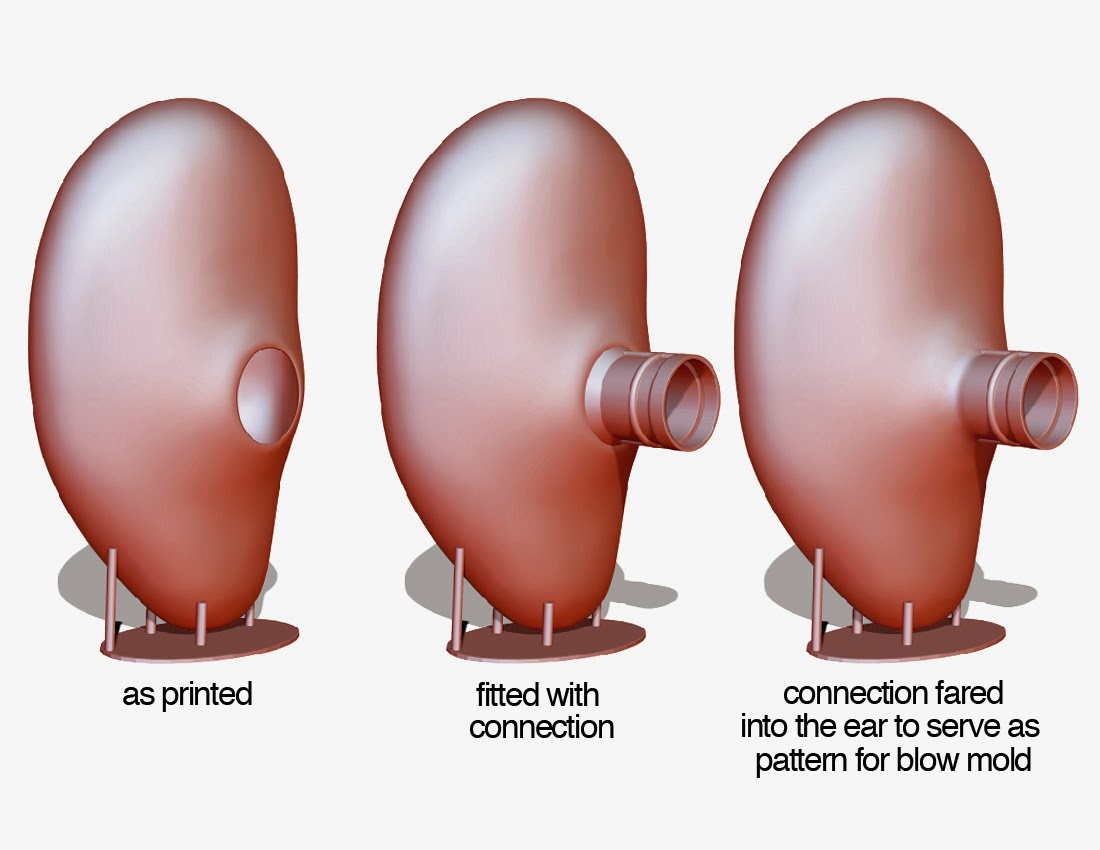

The prototype began it's life in Zbrush. First, I modeled a solid ear full of rollicing and rolling shapes. It had to be cartoonish and toy like but, it also had to contain an aspect of realism or, at least as much as the blow molding process would allow. From that model, I extracted a shell in order to better illustrate the cross section and provide a working mesh for a 3D print. Though the finished prototype incorporates existing fittings to ensure a perfect fit with the tubes, I built the fittings in Zbrush as well in order to show that the toy will feature both a male and female ear as the tubes have both a male and female end.

Before printing, bases and supports were added to the ears so as to facilitate an upright printing of both of them at the same time. The ZTL. file was then decimated to reduce the poly count and converted to an STL. file for slicing.

The ears were printed in ABS on a 3d Systems Cube X printer. Though PLA may be more eco friendly as it's basically made from corn, it's much harder to finish, whereas ABS loves being polished out with acetone and a skillful touch. The Fittings were glued into place. The ears were painted and the whole thing worked like a magic trick.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.